When your signature product depends on super-premium ice cream, consistency is critical. Any change to the air’s temperature or moisture content can mess with quality of frozen treats like the ice cream sandwiches that are Portland-based Ruby Jewel’s claim to fame.

Ruby Jewel minimizes the use of stabilizers in its products, said Steve Panos, the company’s director of operations. That means the sandwiches need to stay perfectly frozen to keep ice crystals from forming. The result is a richer, creamier ice cream — but also more complexity for Panos and his team.

“We have a really narrow temperature window. We’re trying to maintain between -10 and -20 degrees Fahrenheit at all times,” he said. “We know as soon as we start warming above that, the quality of our product starts to degrade.”

In 2020, COVID-19 caused the company to close its retail scoop shops and focus on getting its packaged treats on the shelves of supermarkets and convenience stores.

But Ruby Jewel discovered a problem in the midst of its pandemic pivot.

Its largest freezer wasn’t functioning as well as it could, causing ice to build up and refrigeration parts to burn out. In August of 2020 alone, the company spent $4,500 on freezer parts and repairs, Panos said.

The equipment was about a decade old. Its analog controls depended on readings from a temperature sensor at just one spot in the cold room, which wasn’t ideal for either the quality of Ruby Jewel’s product or the longevity of its equipment.

Fortunately, a solution was in sight.

Thanks to pandemic relief funds plus cash incentives from Energy Trust of Oregon, Panos was able to replace the freezer’s one-size-fits-all mechanical controls with a new system that runs on smart software and only activates as needed.

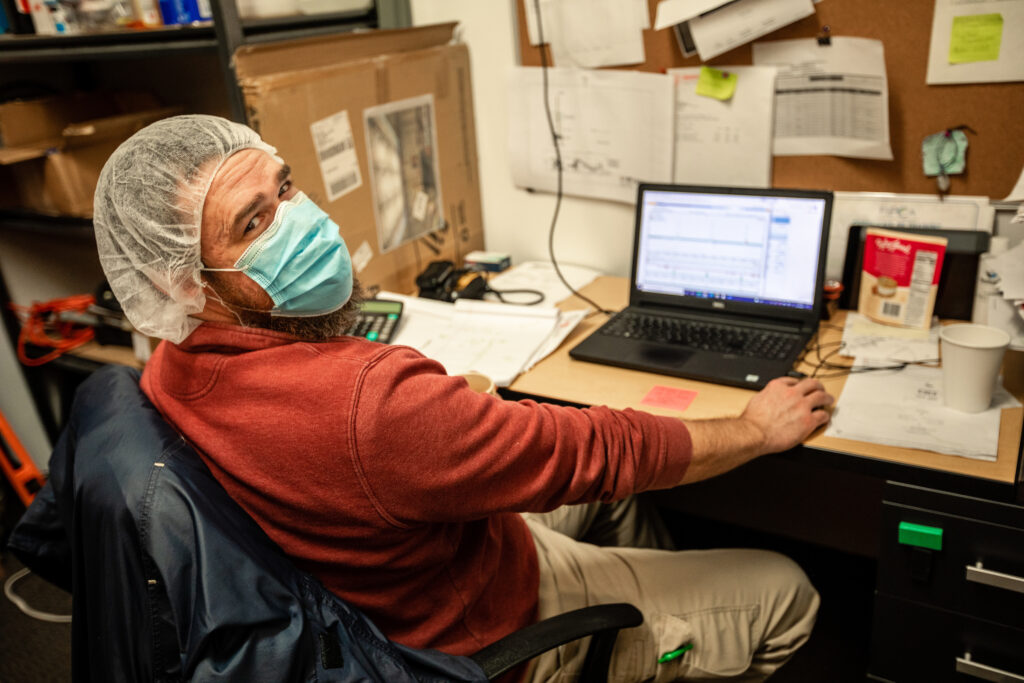

Ruby Jewel’s Steve Panos can track the company’s freezer performance through an online dashboard connected to the refrigeration systems smart controls.

Working with National Energy Conservers, Inc. (NECI), a trusted contractor with Energy Trust of Oregon, Ruby Jewel installed the smart controls in late summer, when the demands on its freezers were the highest.

NECI President Kim Elsey said the new system fills a similar function for Ruby Jewel’s freezers as a pacemaker does for a heart patient. The controls keep refrigeration pumping evenly across all the freezers and alert Panos’ team if there’s an issue.

“To a certain extent, it sounded too good to be true,” Panos said of the upgrade. He credits Elsey for being patient and persistent in explaining the benefits of the new controls, and Energy Trust for validating that the system would live up to its promise.

Elsey had seen the difference smart systems made for his other clients in the region, including fruit company Oregon Berry Packing Co. and ice manufacturer Arctic Glacier. After helping those companies cut their energy use and better maintain their refrigeration equipment, he was sure Ruby Jewel would see similar results.

“The effectiveness of the upgrade wasn’t just about energy savings,” he said. “It was also about reducing food spoilage and having more predictable maintenance.”

The smart controls depend on sensors placed throughout the freezer space. They collect temperature readings and use software to regulate the system as needed, making sure the fans and compressors don’t work overtime.

“The real-time information via monitoring allows us to make quick decisions about how to reach the best possible outcome, which in this case is a stable temperature using the least energy possible,” Panos said.

Using a web-based app, Panos can also pull data from the system to review how it’s performing over time — better making the case for similar energy-saving projects going forward. “It’s just night and day the amount of resources we need to put toward maintaining the freezers,” he said.

Take this August compared to last year, when Ruby Jewel had those huge repair bills. With a few clicks, Panos confirmed that the large freezer had zero maintenance costs in August 2021.

“Seeing is believing,” he said. “Even at a time when companies are hesitant to make the investment, now that I’ve seen it, I wouldn’t question the benefit in the least.”

Learn more about how Energy Trust can help upgrade your business’s industrial equipment at www.energytrust.org/for-business.

Cuando su producto estrella depende de un helado súper premium, la consistencia es fundamental. Cualquier cambio en la temperatura del aire o en el contenido de humedad puede afectar la calidad de las delicias congeladas, como los sándwiches de helado que son el emblema de Ruby Jewel, con sede en Portland.

Ruby Jewel reduce al mínimo el uso de estabilizadores en sus productos, explica Steve Panos, director de operaciones de la empresa. Eso significa que los sándwiches deben permanecer perfectamente congelados para evitar que se formen cristales de hielo. El resultado es un helado más rico y cremoso, pero también más complejo para Panos y su equipo.

“Tenemos un margen de temperatura realmente estrecho. Intentamos mantener entre -10 y -20 grados Fahrenheit en todo momento”, dijo Panos. “Sabemos que en cuanto empezamos a calentar por encima de eso, la calidad de nuestro producto empieza a degradarse”.

En 2020, el COVID-19 hizo que la empresa cerrara sus tiendas minoristas y se centrara en colocar sus golosinas envasadas en las estanterías de los supermercados y tiendas de conveniencia.

Pero Ruby Jewel descubrió un problema en medio de su giro pandémico.

Su congelador más grande no estaba funcionando tan bien como debía, causando que el hielo se acumulara y que las piezas de refrigeración se quemaran. Solo en agosto de 2020, la empresa gastó $4,500 en reparaciones y piezas para el congelador, dijo Panos.

El equipo tenía unos diez años. Sus controles analógicos dependían del sensor de temperatura que estaba en un solo lugar del cuarto frío, lo que no era ideal ni para la calidad del producto de Ruby Jewel ni para la duración de sus equipos.

Afortunadamente, había una solución a la vista.

Gracias a los fondos de ayuda por la pandemia y a los incentivos en efectivo de Energy Trust of Oregon, Panos pudo sustituir los controles mecánicos del congelador por un nuevo sistema que funciona con un software inteligente y se activa solo cuando es necesario.

Steve Panos, de Ruby Jewel, puede monitorear el rendimiento de sus congeladores a través de un panel en línea conectado a los controles inteligentes de los sistemas de refrigeración.

Trabajando con National Energy Conservers, Inc (NECI), un contratista de confianza de Energy Trust of Oregon, Ruby Jewel instaló los controles inteligentes a finales del verano, cuando la demanda de sus congeladores era mayor.

El presidente de NECI, Kim Elsey, dijo que el nuevo sistema cumple una función similar para los congeladores de Ruby Jewel como lo hace un marcapasos para un paciente cardíaco. Los controles mantienen el bombeo de la refrigeración de forma uniforme en todos los congeladores y alertan al equipo de Panos si hay algún problema.

“Hasta cierto punto, parecía demasiado bueno para ser verdad”, dijo Panos sobre la actualización. Le da crédito a Elsey por su paciencia y persistencia a la hora de explicar las ventajas de los nuevos controles, y a Energy Trust por validar que el sistema cumpliera su promesa.

Elsey había visto la diferencia que suponían los sistemas inteligentes para sus otros clientes de la región, como la empresa de frutas Oregon Berry Packing Co. y el fabricante de hielo Arctic Glacier. Después de ayudar a estas empresas a reducir su consumo energético y a mejorar el mantenimiento de sus equipos de refrigeración, estaba seguro de que Ruby Jewel obtendría resultados similares.

“La eficacia de la actualización no era solo el ahorro de energía”, dijo Panos. “También se trataba de reducir el deterioro de los alimentos y tener un mantenimiento más predecible”.

Los controles inteligentes dependen de sensores colocados en todo el espacio del congelador. Recogen las lecturas de temperatura y utilizan un software para regular el sistema según sea necesario, asegurándose de que los ventiladores y compresores no trabajen horas extras.

“La información en tiempo real a través de la monitorización nos permite tomar decisiones rápidas sobre cómo alcanzar el mejor resultado posible, que en este caso es una temperatura estable utilizando la menor energía posible”, dijo Panos.

Gracias a una aplicación web, Panos también puede extraer datos del sistema para revisar su rendimiento a lo largo del tiempo, lo que permite justificar mejor proyectos similares de ahorro energético en el futuro. “El cambio en la cantidad de recursos que tenemos que dedicar al mantenimiento de los congeladores ha sido como la diferencia entre la noche y el día”, afirmó Panos.

Comparando este agosto con el del año pasado, cuando Ruby Jewel tuvo esas enormes facturas de reparación. Con unos pocos clics, Panos confirmó que el congelador grande tenía cero costos de mantenimiento en agosto de 2021.

“Ver es creer”, dijo Panos. “Incluso en un momento en el que las empresas dudan en hacer la inversión, ahora que lo he visto, no cuestionaría el beneficio en lo más mínimo”.

Obtenga más información sobre cómo Energy Trust puede ayudar a mejorar los equipos industriales de su empresa en www.energytrust.org/paranegocios/procesador-de-alimentos.