Increased energy use over time can be the result of failing or malfunctioning equipment. One often-overlooked contributor to higher utility costs is faulty steam traps that don’t seal properly. Testing your steam traps on an annual basis will keep you informed of any performance changes that could be a sign they are malfunctioning and need to be replaced or repaired.

What are steam traps

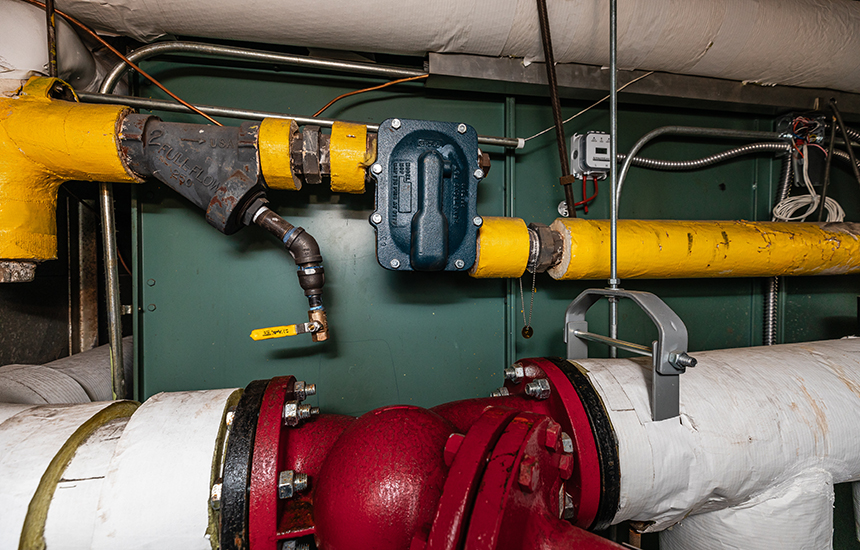

Healthcare facilities, schools and large commercial properties often rely on steam systems for heat. Steam traps are valves in these systems that remove liquid water (condensate) while retaining steam. Steam cools and becomes condensate when it leaves a boiler and travels through pipes to be used as a heat or power source. Steam traps capture that condensate and return it to the boiler to be reheated into steam.

There can be dozens of steam traps per system, depending on the size of the building. Each one of them plays an important role in keeping a steam system running efficiently.

How to tell if a steam trap is malfunctioning

Steam traps fail due to corrosion, sudden pressure changes (water hammer) and debris in the water supply. You can check the performance of your steam traps visually while wearing safety glasses. If you can see steam, that means there’s a leak.

Another method is measuring input and output temperatures. If there is a large drop in steam temperature towards the end of the system compared to the boiler, chances are steam is leaking out somewhere. Special equipment can also be used to measure sound frequencies and detect leaks.

If you want support evaluating your steam traps or are still unsure of their condition, there might be an Energy Trust of Oregon trade ally in your area who can help.

Benefits of properly working steam traps

When steam traps are fully sealed, boilers operate more efficiently. Avoiding steam leaks, small or large, prevents wasteful increases in energy and water usage.

Replacing or repairing faulty steam traps will result in a better, more effective steam system. New steam traps can also reduce the frequency of maintenance and associated repair costs since there’s less load on the boiler. Properly functioning traps can also help prevent property damage caused by leaking steam.

Ready to repair or replace your steam traps?

While preventative care and a consistent maintenance schedule can extend the lifespan of your steam traps, they do wear out over time. In 2023, Energy Trust helped 16 businesses and organizations replace or repair 207 steam traps. These efforts will prevent nearly 1,200 tons of carbon dioxide emissions annually, which is like taking 240 cars off the road for a year.

When it’s time to replace or repair your steam traps, follow these three steps to make them more energy efficient, help lower your energy bills and reduce your out-of-pocket expenses:

- Determine how your project can qualify for up to $500 per steam trap in cash incentives.

- Install or repair qualifying energy-efficient steam traps and submit an incentive application.

- Connect with an Energy Trust advisor to learn what other resources you could benefit from.