A 10-year commitment to energy efficiency has helped Biomass One, a 28.5-megawatt cogeneration facility in White City, slash 4.1 million kilowatt hours from its annual energy use.

Biomass One, which burns wood waste to generate renewable power, first worked with Energy Trust of Oregon in 2009 to boost efficiency in its primary process. Installing new fans and motors with variable frequency drives delivered annual savings of 3.35 million kWh. A $344,000 Energy Trust cash incentive helped defray the $708,000 installation cost.

Starting in 2017, plant personnel dedicated five years to replacing 99% of the facility’s lighting with new, energy-efficient LEDs. “We started in our maintenance shop, where our metal halide lamps had reached the end of their useful life,” said Louis Eck, purchasing agent at Biomass One. That project worked so well, Biomass One moved on to the turbine building, replacing existing lighting with high-bay LEDs controlled by occupancy sensors that dim the lights when no one is underneath. “LEDs have made the turbine building much brighter and safer for employees,” said Eck. “They really appreciate the extra light.”

Outside in the fuel yard, dozens of 1,000-watt lighting fixtures gave way to 300-watt LED fixtures mounted on top of buildings and stacks and above the fuel pile. Here Biomass One got innovative with controls. “The wood debris makes it dusty, so we wired all the exterior lights so they’re controlled by a single photocell located out of the dust zone,” said Eck. “We operate 24/7, so LEDs brought a significant improvement in security and safety. Employees no longer need to use flashlights at night.”

Altogether, lighting improvements trimmed the plant’s annual electricity use by 555,000 kWh. The project cost was approximately $72,000 because Biomass One did all the work in-house, buying LEDs from their local vendor. Energy Trust cash incentives totaling $39,000 made the one-year return on investment more favorable.

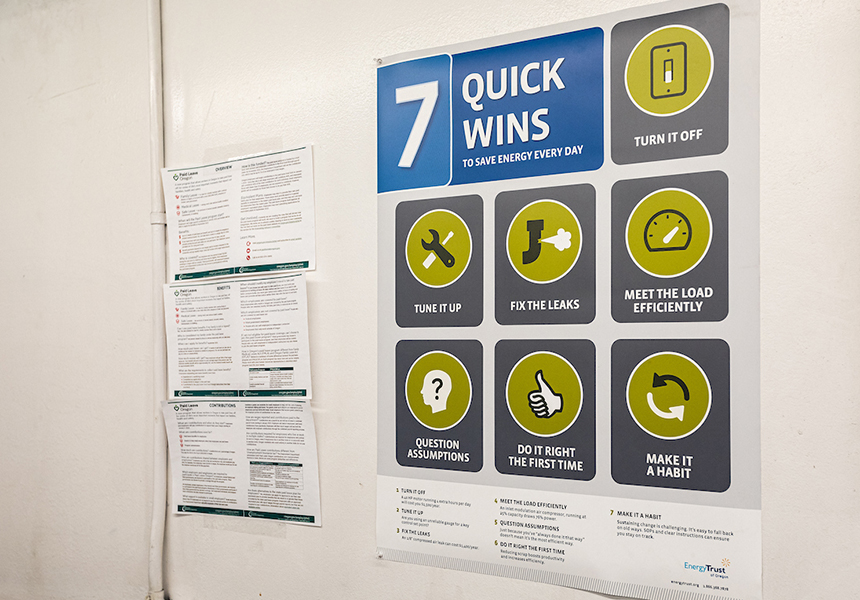

In 2021 and 2022, Biomass One enrolled in Strategic Energy Management (SEM)—an Energy Trust offering that helps organizations identify no-or low-cost operations and maintenance improvements that deliver lasting savings. The facility formed a plant-wide energy team and received training on developing comprehensive energy management practices. Biomass One is making simple changes, like shutting down its 500-horsepower hog motor during lunch, reducing unneeded pressure in its compressed air system and removing redundancy in the condensate pumps serving its generator.

“We’re not done yet, we know we have more work to do,” said Eck. “We’re a renewable energy power plant, so energy we save is energy we can sell to Pacifi-Corp and provide to Oregonians.”

Learn more about industrial equipment incentives and lighting and lighting control upgrades for your business.