Nestled in the high desert of Lakeview, Oregon—one of the most rural communities in the state—Pacific Pine Products has grown from a small family shop into a leading wood door manufacturer. Today, the company employs 85 people in a town of just about 3,000. For owner Greg Larson, success is about more than producing finely crafted doors. It’s about keeping the business competitive, providing good jobs, and finding ways to sustain both the environment and the community.

For more than 15 years, Energy Trust has been a steady partner in that effort, providing over $413,000 in incentives. These investments have led to over $263,000 in annual energy savings, a cleaner workplace, and improved production efficiency—showing how even small rural businesses can achieve big results through energy innovation.

Pacific Pine Products employs 85 people in a town of just about 3,000.

From “low-hanging fruit” to bigger gains

The collaboration began with what Larson calls “low-hanging fruit.” Running a fleet of trucks across the West, Pacific Pine generated a steady stream of waste motor oil. Instead of paying for disposal, Larson worked with Energy Trust to install waste-oil heaters, allowing him to shut off the inefficient heaters and save on annual electricity costs. The project turned a waste product into reliable heat for spaces that had previously gone unheated, cutting costs and improving comfort for employees. Because the company didn’t generate enough oil to sustain the system, Larson began collecting oil from neighbors, turning a waste stream into a community resource.

Cleaner air and warmer workplaces

As the company expanded, so did its energy, productivity, and environmental challenges. For years, Pacific Pine relied on cyclone separators to collect sawdust and debris. When built in 1995, these cyclones were best practice. But, while inexpensive, these systems were energy inefficient, and released particulates into the air, creating maintenance headaches, air-quality issues, and an eyesore for the community.

When a new 15,000-square-foot facility was built, Larson seized the opportunity to install a state-of-the-art “bag house” system in 2021. Unlike the old cyclones, bag houses use high-efficiency filters to capture dust, while returning warmed, filtered air back into the building. The results were immediate: cleaner air for employees, quieter operations for nearby neighbors, and reduced heating costs during Lakeview’s long winters. By 2023, two more bag houses replaced the remaining cyclones, transforming the company’s air quality and energy use, while significantly reducing the electric fan load.

Pacific Pine offset $486,000 in project costs and now saves more than 3.3 million kilowatt-hours annually.

Smarter production, lower energy intensity

Another major step forward came with the installation of a cut-line optimizer and flying saw system. Previously, workers used manual chop saws—slow, labor-intensive, and prone to safety hazards. The new system uses scanners and automation to maximize recovery of valuable lumber, increasing yield by 5–10 percent while allowing production to consolidate from two shifts to one. That change reduced operating hours for compressors, blowers, and lighting, cutting energy use while boosting throughput and safety.

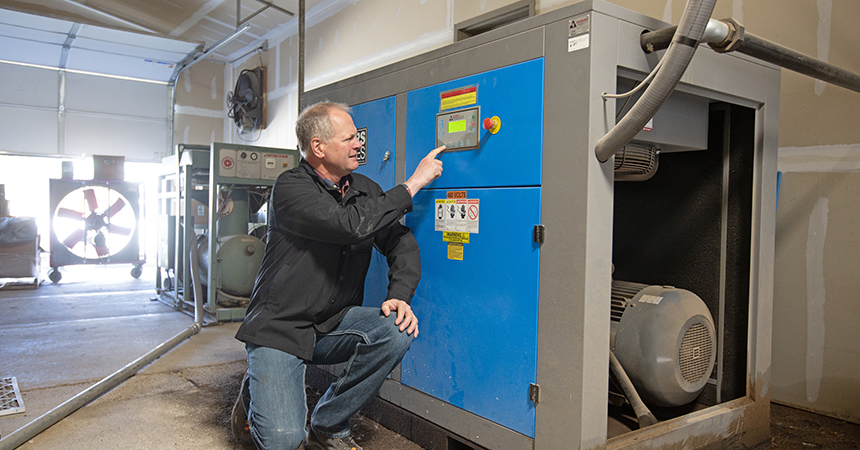

Additional upgrades supported by Energy Trust included a modern air compressor system and facility-wide LED lighting. Together, these improvements lowered energy consumption, reduced maintenance demands, and created brighter, safer, more comfortable work environments.

Larson sets controls on the upgraded air compressor.

Benefits that ripple outward

The cumulative effect of these projects has been substantial. With Energy Trust support, Pacific Pine offset $486,000 in project costs and now saves more than 3.3 million kilowatt-hours annually—the equivalent of powering over 300 Oregon homes. Warmer, brighter workspaces have boosted morale, while cleaner operations improve health and safety. Lower energy intensity makes the company more competitive in a challenging global market, and cost stability allows Pacific Pine to provide wages, benefits, and community sponsorships that enrich life in Oregon’s highest-elevation town.

For Larson, the partnership is about more than incentives—it’s about collaboration. “Because we had that relationship, I could quickly bounce ideas off Energy Trust to find opportunities,” he explains. Site visits often sparked new projects, from lighting to air compressors to advanced manufacturing systems. Incentives helped fast-track investments, allowing Pacific Pine to “do projects the right way, start to finish, without cutting corners.”

Hector Castro sets up this moulder, a machine that shapes and profiles wood.

A model for rural businesses

Larson believes other small and rural business owners can follow a similar path. “Any small business needs to be aware, network, and explore what’s out there,” he says. “Once you understand what’s available and the benefits, the decision isn’t that hard.”

For Pacific Pine Products, those decisions have paid off—reducing costs, strengthening community, and proving that in even the most rural corners of Oregon, innovation and efficiency go hand in hand.

Key project results include:

- Received $413,308 in Energy Trust incentives

- $263,000 saved annually on utility bills

- 3 million kWh/year in electricity savings

- Cleaner environment, improved production efficiency, better workplace for employees.

Learn more about the offers Energy Trust has for industrial facilities.

You can also reach our team directly to answer any questions you have. Give us a call at 1.866.202.0576 or email at production@energytrust.org.