Treating wastewater isn’t just about community health and safety. It can also be a way to increase energy flexibility and lower costs. A recent upgrade at the Grants Pass Wastewater Treatment Plant is an example of the projects that are moving the city toward its energy efficiency and sustainability goals.

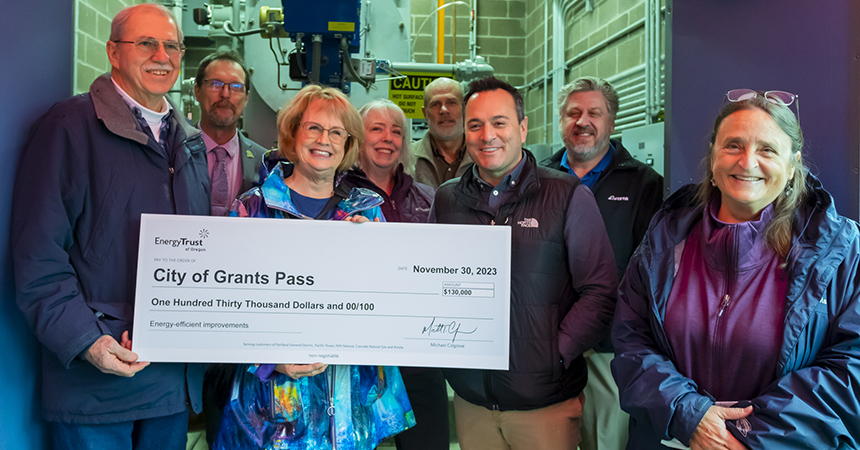

The plant installed a new dual-fuel boiler and heat exchanger system that is using biogas produced at the plant as fuel to meet its thermal energy needs, offsetting the cost of purchasing natural gas. The project also received $130,000 in cash incentives from Energy Trust of Oregon, enabling the team to choose the upgrade option with the lower operating cost.

“This project has not only helped Grants Pass toward its greenhouse gas emission goal of net zero by 2045, but in the months since the project has been up and running the Wastewater Treatment Plant has on utility bills by generating its own clean energy,” said Jason Canaday, Grants Pass public works director. Those savings are currently more than $53,000.

New system recycles treatment byproduct

The Grants Pass Wastewater Treatment Plant serves approximately 14,000 homes and businesses in the area. The wastewater passes through a 164-mile network of pipes to reach the treatment facility where the water and sludge are separated and treated.

The sludge is processed in an anaerobic digester that requires heat to maintain the correct balance of biological activity. Prior to the upgrade, the facility’s 70-horsepower natural gas boiler and heat exchanger system that supports the digester were showing their age and needed to be repaired or replaced.

The treatment plant’s engineering team, with support from Energy Trust, evaluated two options: one that would keep the existing natural gas-fueled boiler and replace the heat exchanger, and the second that would install the dual-fuel system. By including the cash incentive from Energy Trust, the dual-fuel system penciled out as the preferred investment.

With the new 40-horsepower dual-fuel boiler, the Grants Pass Wastewater Treatment Plant is able to use the biogas it already produces to meet the plant’s thermal demand, saving an estimated 52,000 therms per year. Plant Superintendent Gary Brelinski said, “I was spending $3,000-$4,000 a month on natural gas in the winter. The savings from our new system are good!”

The upgrade project included a more robust heat exchanger. The new six-inch concentric tube heat exchanger loops back and forth multiple times instead of just once, providing more heating surface area in the same space.

Proximity has improved efficiency as well. “With the boiler sitting on top of the digester instead of 200 feet away, we’ve cut way down on heat waste,” said Brelinski. The facility has been able to keep the old natural gas boiler to heat the main building only.

Brelinski recommends this new system to other municipalities and suggests they learn more by talking with facilities that already have one in place, as well as Energy Trust and equipment suppliers. “The redundancy and reliability of the system, plus the energy savings are definitely worth it. The new boiler gives us the flexibility to use natural gas if there’s ever a time we’d need to in the future.”

Taking action now for the future

The City of Grants Pass has been working to improve its energy efficiency and increase sustainability for more than a decade, replacing lighting with LEDs, installing solar panels, adding hybrid vehicles and improving facility operations. In 2023, the city further defined its efforts in the Grants Pass Sustainability and Energy Action Plan. Energy Trust has supported development of this collaborative and comprehensive road map to build resiliency into the region’s future.

“Cities are not going anywhere,” said Karen Chase, Energy Trust’s Southern Oregon outreach manager. “The energy efficiency and renewable energy investments they are making today are meaningful long into the future.” She points out that the dual-fuel boiler upgrade at the Grants Pass Wastewater Treatment Plant aligns perfectly with the city’s . “The boiler is emblematic of the kinds of projects that are more efficient and save the city money going forward. The planning team envisioned these for all of the city’s enterprises.”

If your organization or municipality is interested in ways to improve efficiency and lower energy costs now and for the years ahead, contact Energy Trust at 1.866.202.0576 or email production@energytrust.org.