When Skip Technology relocated to Portland, it was lucky to find a space that had enough room for the huge battery components it designs. But old, inefficient fluorescent lights made it hard to see in the lab, so the startup partnered with Energy Trust of Oregon for an upgrade.

One of the big issues we need to solve as more renewable energy sources come online is the question of storage. How can we harvest clean wind and solar energy to help power the U.S. economy, then release it on demand?

Oregon startup Skip Technology thinks large-scale batteries are the answer, but these need to be quickly, safely and inexpensively produced from materials that are readily available.

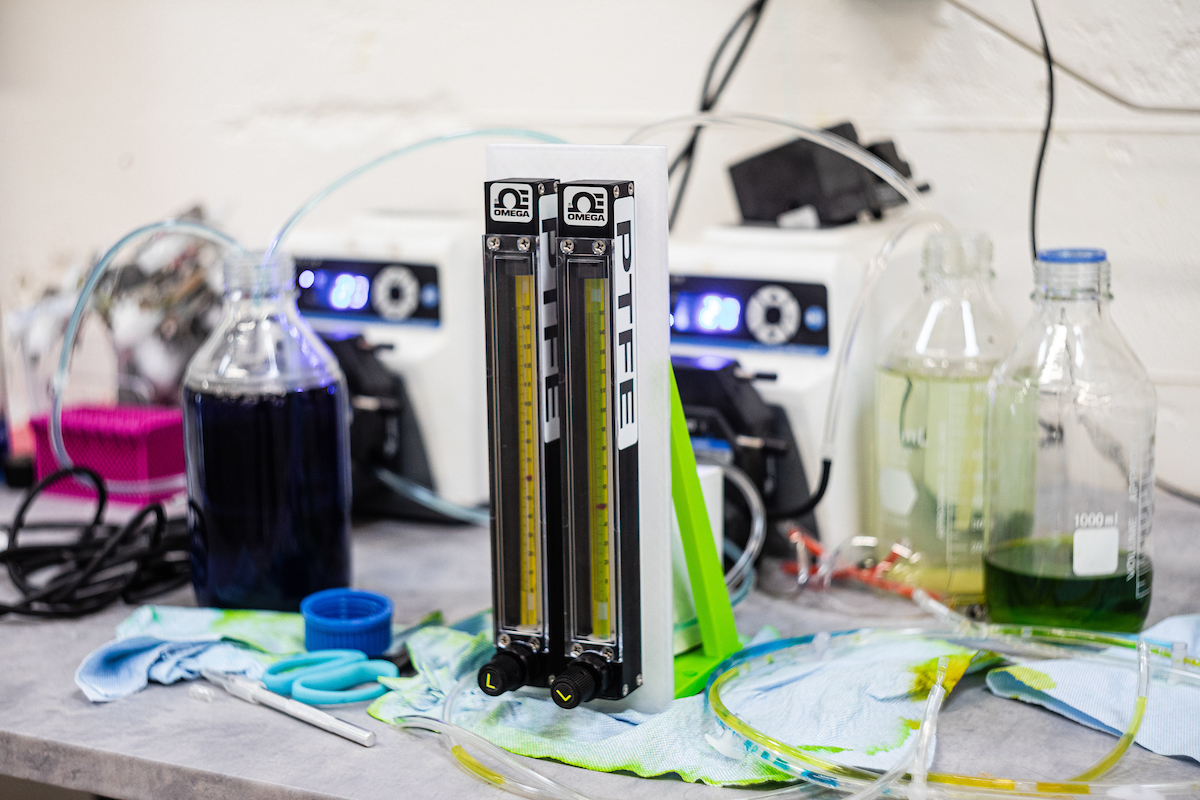

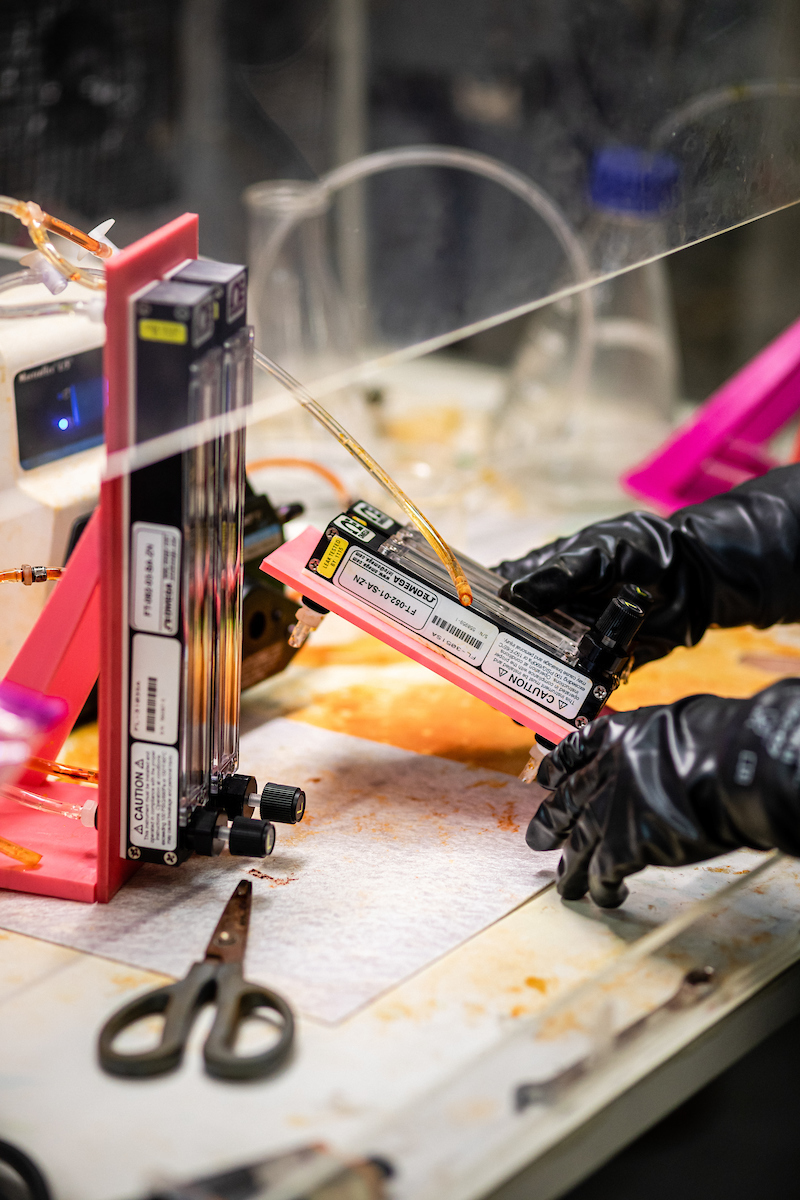

With support from the National Science Foundation and other funders, the company is working on a type of battery that could meet those needs. Called a flow battery, it combines two basic chemicals, hydrogen and bromine, in a reaction that creates energy. To reach industrial scale, each battery would be the size of a shipping container. It could be customized to a customer’s needs and combined in a series to efficiently supply power to the electrical grid.

“This is a high risk, high reward sort of thing,” said Skip Tek co-founder Brennan Gantner. “The odds of success are low. But the payoff if we’re successful is very, very high. And we figured that if we have enough people trying these high reward projects, one of us is going to make it through.”

To bring its ideas to the next level, the startup first needed a large lab space to test and build the prototypes for its chemical batteries. Skip Tek started out in a lab at Oregon State University, but Gantner’s family lives in Portland. When his kids’ school went remote during the COVID-19 pandemic, the commute to Corvallis became a “nonstarter.”

“We basically decided we had to be in Portland,” he said. “And if we couldn’t find a chemical lab in Portland, we were going to build one ourselves. So that’s what we ended up doing.”

Skip Tek co-founder Brennan Gantner and his partners are betting on their ability to develop an industrial-scale battery from their retrofitted chemical lab in Portland

Skip Tek found a 5,000-square-foot site in Portland’s Central Eastside Industrial District that had high ceilings and roll-up doors that would allow the team to bring shipping containers inside.

“We were pretty lucky to find the space that we have, with a price tag that currently a two-and-a-half-person startup can afford,” Gantner said. Fortunately, the landlord would let them build it out as a chem lab.

The retrofit included safety features like chemical hoods and ventilation, new heating and cooling equipment, and an office area to house the team’s desks and the 3-D printers they use to make scaled-down models of the batteries. About the only thing it didn’t cover was the lights — old fluorescent tubes suspended about 25 feet above the lab floor.

“We had negotiated as hard as we could to get a lot of building improvements done,” Gantner said. “The lighting was kind of like ‘well, it’s not perfect, but fluorescents aren’t the worst thing. We’ve probably pushed the landlord as hard as we can, so if we have to cave on something, it’s a good thing to cave on.”

Skip Tek’s luck held, though. When the company moved into the new space in July of 2021, Gantner reached out to Portland General Electric to set up utility service. And a PGE rep mentioned that Energy Trust of Oregon might be able to upgrade Skip Tek’s lights at no cost.

Sure enough, the fluorescent lights in the lab were the kind that can be replaced with efficient LEDs for free through Energy Trust’s no-cost lighting offer for small businesses. “It was a happy, happy bonus that we got it done in another way,” Gantner said. “There’s literally almost no downside for us — it’s perfect.”

All told, Gantner spent about three hours on the project, from the initial assessment through having an electrician install the new lighting system. And the upgrade will save the company $600 a year on utility bills.

“We’re a very lean organization, so $600 is a good chunk of change for us,” Gantner said; it could cover a week of someone’s salary or allow the lab to buy another piece of equipment.

“As a startup, we don’t make any money right now. We exist solely on the money that we raised from investors or for grants. Any place we can save money and still be productive is absolute gold.”

Could your business benefit from energy-efficiency upgrades? Check out the latest no- and low-cost tips and resources to help your business run better, visit www.energytrust.org/for-business or call 1.888.777.4479.

Uno de los grandes asuntos que tenemos que resolver a medida que se conectan más fuentes de energía renovable es la cuestión del almacenamiento. ¿Cómo podemos recoger energía eólica y solar limpia para ayudar a alimentar la economía de Estados Unidos y luego liberarla cuando se necesite?

La nueva empresa de Oregon, Skip Technology, cree que las baterías a gran escala son la respuesta, pero deben producirse de forma rápida, segura y económica a partir de materiales fácilmente disponibles.

Con el apoyo de la National Science Foundation y otros patrocinantes, la empresa está trabajando en un tipo de batería que podría satisfacer esas necesidades. Llamada batería de flujo, combina dos sustancias químicas básicas, hidrógeno y bromo, en una reacción que crea energía. Para alcanzar la escala industrial, cada batería tendría el tamaño de un contenedor de barco. Podría adaptarse a las necesidades del cliente y combinarse en serie para suministrar energía a la red eléctrica de forma eficiente.

“Se trata de algo de alto riesgo y alta recompensa”, afirmó el cofundador de Skip Tek, Brennan Gantner. “Las probabilidades de éxito son bajas. Pero la recompensa si tenemos éxito es muy, muy alta. Y pensamos que si hay suficientes personas que intentan estos proyectos de alta recompensa, uno de nosotros va a salir adelante”.

Para llevar sus ideas al siguiente nivel, la startup necesitaba primero un gran espacio de laboratorio para probar y construir los prototipos de sus baterías químicas. Skip Tek empezó en un laboratorio de la Oregon State University, pero la familia de Gantner vive en Portland. Cuando la escuela de sus hijos pasó a ser remota durante la pandemia del COVID-19, el viaje a Corvallis se convirtió en un obstáculo.

“Básicamente decidimos que teníamos que estar en Portland”, dijo Gantner. “Y si no podíamos encontrar un laboratorio químico en Portland, íbamos a construir uno nosotros mismos. Así que eso es lo que terminamos haciendo”.

El cofundador de Skip Tek, Brennan Gantner, y sus socios apuestan por su capacidad para desarrollar una batería a escala industrial desde su laboratorio químico reacondicionado en Portland.

Skip Tek encontró un terreno de 5,000 pies cuadrados en el distrito industrial Central Eastside de Portland que tenía techos altos y puertas enrollables que permitirían al equipo introducir contenedores de transporte en el interior.

“Tuvimos mucha suerte de encontrar el espacio que tenemos, con un precio que actualmente se puede permitir una empresa de dos personas y media”, dijo Gantner. Afortunadamente, el propietario les permitió construir un laboratorio químico.

La remodelación incluyó elementos de seguridad como campanas químicas y ventilación, nuevos equipos de calefacción y refrigeración y una zona de oficinas para tener los escritorios del equipo y las impresoras 3D que utilizan para hacer modelos a escala reducida de las baterías. Lo único que no se incluyó fue la iluminación: viejos tubos fluorescentes suspendidos a unos 25 pies sobre el piso del laboratorio.

“Habíamos negociado todo lo que pudimos para conseguir muchas mejoras en el edificio”, dijo Gantner. “La iluminación era algo así como ‘bueno, no es perfecta, pero los fluorescentes no son lo peor’. Probablemente hemos presionado al propietario todo lo que hemos podido, así que, si tenemos que ceder en algo, es una buena cosa en la que ceder”.

Sin embargo, la suerte de Skip Tek se mantuvo. Cuando la empresa se trasladó al nuevo espacio en julio de 2021, Gantner se comunicó con Portland General Electric para contratar los servicios públicos. Y un representante de PGE mencionó que Energy Trust of Oregon quizás podría actualizar las luces de Skip Tek sin costo alguno.

Sin duda, las luces fluorescentes del laboratorio eran del tipo que puede sustituirse por LED eficientes de forma gratuita a través de la oferta de iluminación sin costo de Energy Trust para pequeñas empresas. “Fue un bonus feliz, feliz porque la conseguimos de otra manera”, dijo Gantner. “Literalmente no hay casi ningún inconveniente para nosotros, es perfecto”.

En total, Gantner invirtió unas tres horas en el proyecto, desde la evaluación inicial hasta entregar el papeleo del incentivo y la instalación del nuevo sistema de iluminación por parte de un electricista. La actualización ahorrará a la empresa $600 al año en facturas de servicios públicos.

“Somos una organización muy modesta, así que $600 es una buena cantidad de dinero para nosotros”, dijo Gantner. Podría cubrir una semana de salario de alguien o permitir al laboratorio comprar otra pieza de equipo.

“Como empresa emergente, ahora mismo no ganamos dinero. Existimos únicamente con el dinero que recaudamos de los inversores o de las subvenciones. Cualquier lugar en el que podamos ahorrar dinero y seguir siendo productivos es oro puro”.

¿Podría su empresa beneficiarse de las mejoras de eficiencia energética? Consulte los últimos consejos y recursos gratuitos y de bajo costo para ayudar a que su empresa rinda más, visite www.energytrust.org/paranegocios/alumbrado o llame al 1.888.777.4479.